Analysis of the category characteristics of non-woven fabrics

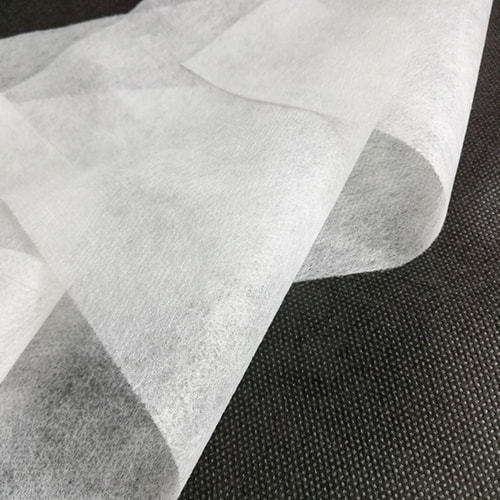

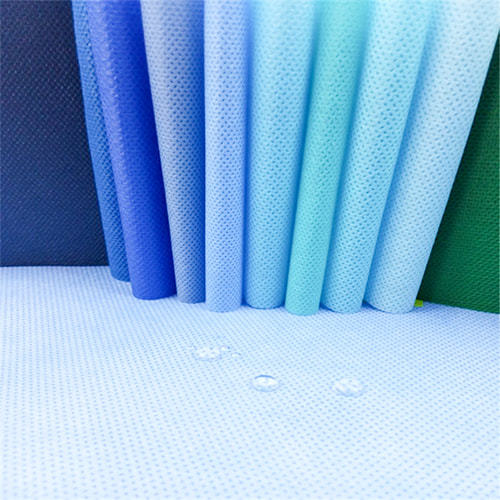

Nowadays, there are many types of non-woven fabrics with different characteristics. To choose a good non-woven fabric, you must first understand the characteristics of various types of non-woven fabrics. Only by being familiar with the product can you get the first-class goods. Today we will introduce the various categories and characteristics of non-woven fabrics in detail.

1. Properties of engineered nonwovens

Engineering according to more stringent process properties can lead to significant savings and improvements in nonwoven properties such as isotropic strength, porosity, volume, etc. Nonwoven properties, in practical applications, are determined by experience at the factory level. More generally, the performance of nonwoven products can be modified as needed to better meet customer needs. The two priority techniques mentioned above need to target specific structural characteristics.

2. High specific strength non-woven fabric

New web bonding technology; novel construction that provides a higher strength-to-weight ratio and incorporation of new high-strength fibers. An important challenge is therefore to find ways to achieve this while also achieving equal strength in every direction on the fabric. Since a high proportion of the cost of the final product is attributed to the increased strength of the input fiber, it must be achieved without increasing the input of material. The improved strength must be achieved without affecting other performance-related properties of the fabric. Other nonwoven applications, such as filters for the mining industry and some building materials products, will also benefit from improved strength. This is especially important where mining applications work, as those mining infrastructure must endure the severe challenges of loading geotextiles. The Holy Grail in geotextiles are fabrics that improve strength/weight.

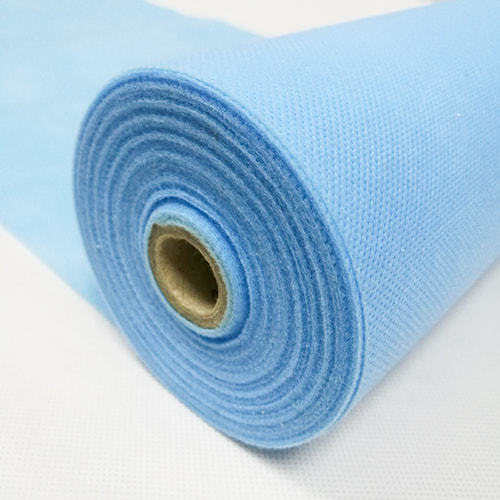

3. Lightweight non-woven products

There should be the use of finer fibers to increase the surface area of the fibers for a given quality and the development of innovative structures to improve performance without increasing mass. Also in many applications with a high ratio such as automotive insulation there is a continuing need for a reduction in weight of components, the cost of input materials accounting for the cost of the final product. Lightweight nonwoven products, while maintaining or improving product properties especially for insulation and filtration - are critical to the future viability of many nonwoven production companies.

英语

英语 中文简体

中文简体