Environmentally friendly: The environmental friendliness of a fabric depends on several factors, including the raw materials used, the manufacturing process, and its end-of-life disposal. To create an environmentally friendly spunbond non-woven fabric, one would typically focus on using sustainable and renewable raw materials, such as plant-based fibers or recycled materials. Additionally, adopting eco-friendly production methods and ensuring recyclability or biodegradability of the fabric can contribute to its overall environmental friendliness.

Flexible: Spunbond non-woven fabrics are generally known for their strength and stability rather than flexibility. However, by modifying the fabric's composition, it is possible to enhance its flexibility while still maintaining its integrity. Adding elastic materials or incorporating stretchable fibers into the fabric can help achieve a certain level of flexibility.

Non-toxic: To create a non-toxic spunbond non-woven fabric, it is crucial to select raw materials that are free from harmful chemicals and toxins. Using organic or naturally derived fibers and avoiding the use of hazardous additives during the manufacturing process are essential steps to ensure non-toxicity. Additionally, conducting rigorous testing and adhering to relevant safety standards can help verify the fabric's non-toxic nature.

Odorless: Odorless fabrics can be achieved by using high-quality raw materials and ensuring that no unpleasant-smelling substances are introduced during the production process. Proper handling and storage of the fabric after manufacturing are also essential to prevent any odor absorption.

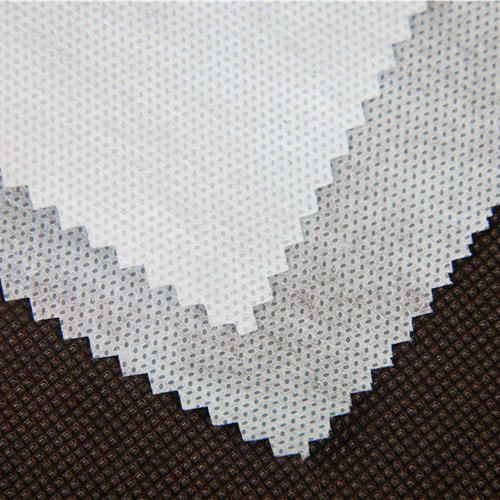

Breathable: Breathability in fabrics is typically associated with their ability to allow air and moisture vapor to pass through. Spunbond non-woven fabrics tend to have lower breathability compared to natural fibers like cotton or linen. However, by incorporating specific perforations, using breathable coatings or laminates, or combining the spunbond non-woven fabric with other breathable layers, it is possible to enhance its breathability to some extent.

Waterproof: Spunbond non-woven fabrics are inherently not waterproof, as they have an open structure that allows water to pass through. However, it is possible to add a waterproof coating or lamination to the fabric's surface to provide water resistance or waterproofing properties. These additional treatments can create a barrier that prevents water from penetrating the fabric.

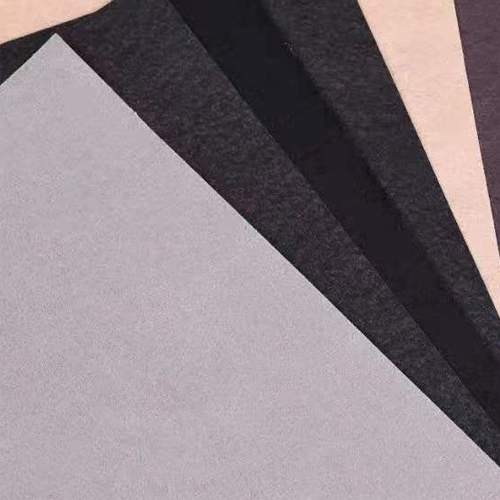

Environmentally friendly, flexible, non-toxic, odorless, breathable and waterproof spunbond non-woven fabric

| Terms of payment and delivery: | 30% deposit70% against copy of bill of lading,Sea Transportation |

| Minimum order quantity: | 1Ton |

| Price: | Consultation |

| Packing details: | PE roll Film packaging |

| Delivery time: | one 40-foot container in 10 days |

| Weight and width range: | 9-150 grams in weight range, 2.5CM-330CM in width |

英语

英语 中文简体

中文简体