How to prevent non-woven fabrics from fouling

(1) Oil-repellent finishing

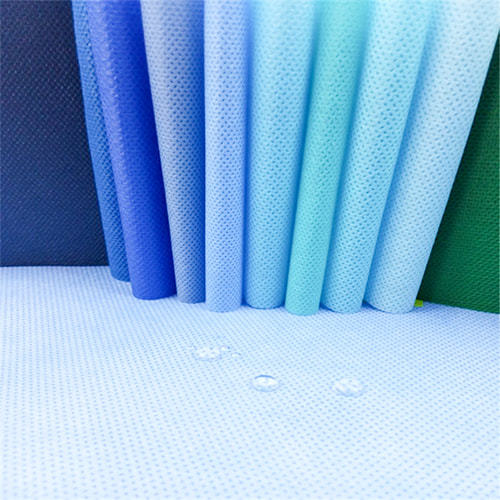

Liquid contaminants are primarily contaminated on the surface of fibers by wetting, and then contaminate the interior of the fabric, between fibers and between yarns by capillary action. The principle is similar to the wetting and penetration of water on the surface of fibers, except that the surface tension of needle punched nonwoven manufacturers oily liquid contaminants is usually smaller than that of water, so the wetting ability of liquid contaminants to non-woven fabrics is strong.

In order to prevent the wetting and spreading of such substances on the fiber surface, the critical surface tension of the fiber surface must be at least lower than the surface tension of the above-mentioned dirt in order to have oil-repellent properties, so that the above-mentioned dirt can resist and prevent it from adhering to the fiber. surface.

(2) Easy decontamination finishing

The actual soiling of nonwovens generally consists of liquids and particles.

The purpose of easy decontamination finishing is mainly to make the oily liquid dirt on the hydrophobic fibers easy to be removed, and because the liquid dirt is often used as the carrier and binder of the particles, if the liquid dirt is easy to wash off, the particles will also be easily removed. remove. The removal of needle punched nonwoven fabric manufacturers dirt from the surface of the non-woven fabric, in addition to factors such as washing conditions, mainly depends on the critical surface tension of the fiber surface, which is related to the surface energy of the non-woven fabric. It has high wettability in liquid medium and low interfacial energy for common oily dirt in air medium, so that it can have a good antifouling effect.

英语

英语 中文简体

中文简体