PP spunbond non-woven fabric is one of the types of non-woven fabrics. The principle of spunbond non-woven fabric is to extrude and stretch the polymer to form continuous filaments, lay it into a network, and then pass through its own bonding and heat treatment. Bonding, chemical bonding or mechanical reinforcement methods that turn the web into a nonwoven. The following editor of Chengxin Nonwovens will talk to you about the introduction of the production technology types of spunbond nonwovens:

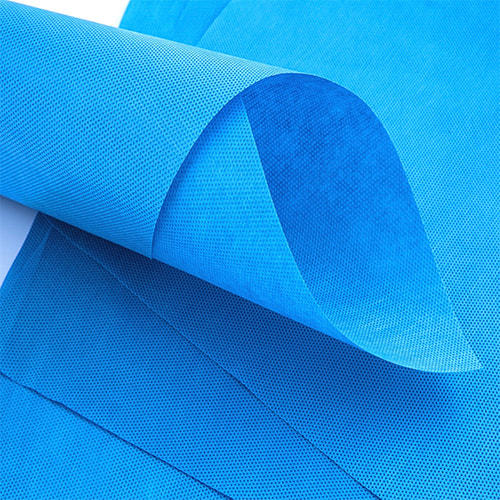

Spunbond non-woven fabric has good high temperature resistance (polypropylene can be used for a long time at 150℃, polyester can be used for a long time at 260℃), aging resistance, UV resistance, high elongation, good stability and air permeability, corrosion resistance , sound insulation, moth-proof, non-toxic. The main materials of spunbond non-woven fabrics are polyester and polypropylene. The main products of spunbond non-woven fabrics are polypropylene and polyester (long fiber, staple fiber) non-woven fabrics. Our common and commonly used applications are non-woven bags, non-woven Textile packaging, etc. The identification of spunbond non-woven fabrics is easier, and the two-way fastness is generally good. Generally, the rolling point of spunbond non-woven fabrics is diamond-shaped.

The spunbond non-woven technologies on the market mainly include Lacoffel technology from Refen, Germany, STP technology from Italy, Kobe Steel technology from Japan, etc. The current situation, especially with Reffin technology becoming the mainstream technology. It has now developed to the fourth generation of technology. It is characterized by the use of negative pressure ultra-high-speed air drafting, and the fiber can be stretched to about 1 denier.

The spunbond non-woven fabric produced by Qingdao Chengxin Non-woven Fabric can also be used as flower packaging cloth, luggage cloth, etc. It has the characteristics of wear resistance, firmness and good hand feeling, making it the best choice for making such products.

英语

英语 中文简体

中文简体