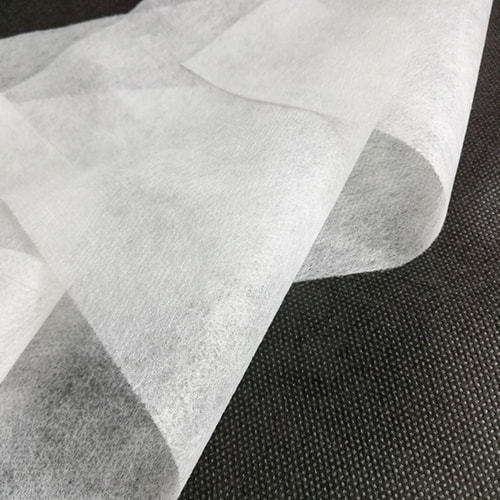

Non-woven fabric is a kind of non-woven fabric, which directly uses high polymer chips, short fibers or filaments to form fibers through air flow or machinery, and then undergoes hydroentanglement, needle punching, or hot rolling reinforcement, and finally after finishing Formed non-woven fabric. A new type of fiber product with a soft, breathable and flat structure, the advantages are that it does not produce lint, is strong, durable, silky soft, and has a cotton feel. Compared with cotton fabrics, non-woven bags are easy to form, and Cheap.

In terms of environmental protection, the raw material of most of the non-woven fabrics currently used is polypropylene, while the raw material of plastic bags is polyethylene. Although the two substances have similar names, they are quite different in chemical structure. The chemical molecular structure of polyethylene has quite strong stability and is extremely difficult to degrade, so it takes 300 years for plastic bags to decompose; while the chemical structure of polypropylene is not strong, the molecular chain can be easily broken, so that it can be effectively degraded , and enter the next environmental cycle in a non-toxic form, a non-woven shopping bag can be completely decomposed within 90 days. Moreover, non-woven shopping bags can be reused more than 10 times, and the pollution to the environment after disposal is only 10% of that of plastic bags.

英语

英语 中文简体

中文简体