Needle Punched Nonwovens Overview and Processing Procedures

Acupuncture non-woven fabrics are a kind of non-woven fabrics. They are made of polyester, polyester and polypropylene raw materials, and are made by multiple needle punches and appropriate heat-pressing treatment. According to different processes and with different materials, tens of thousands of products are made, which are used in all walks of life, and various specifications can be customized according to different purposes.

Overview

Needle-punched non-woven fabric is a kind of dry-laid non-woven fabric. Short fibers are opened, combed, and laid into a fiber web, and then the fiber web is reinforced into a cloth by a felting needle. The needle has a barb, and the fiber web is repeatedly punctured. , The hook belt fiber is reinforced to form a needle-punched non-woven fabric. The non-woven fabric is not divided into warp and weft. Typical products: synthetic leather base fabrics, needle-punched geotextiles, etc.

usual format

Gram weight: (60-800) g/㎡, thickness: 1-8mm width: within 3.2 meters

Machining program

It is made of polyester and polypropylene raw materials, which are carded, combed, pre-needle punched, and main needle punched. A mesh cloth interlayer is added in the center, and then double-layered, air-laid and needle-punched to form a cloth, and the filter cloth after pressing has a three-dimensional structure. The appearance is smooth, the micropores are evenly distributed, the density of the product is good from the surface, the surface of both sides is smooth and the air permeability is good, and it has been proved by the filter on the plate and frame compressor. Need to provide polypropylene and polyester two kinds of raw materials. Practice has proved that non-woven filter cloth has better performance in plate and frame filtration: for example, coal slime treatment in coal preparation plants, and wastewater treatment in iron and steel plants. Wastewater treatment in breweries, printing and dyeing plants. If the filter cloth of other specifications is used, the filter cake will not be pressed dry, and it will be difficult to fall off. After using the non-woven filter cloth, the filter cake is quite dry when the filter pressure reaches 10kg-12kg, and the filter cake when the filter frame is opened. will fall off automatically. When users choose non-woven filter cloth, they mainly consider non-woven filter cloth of different thickness and quality according to the air permeability, filtration accuracy, elongation, etc. For product parameters, please click polyester needled felt and polypropylene needled felt. can be formulated.

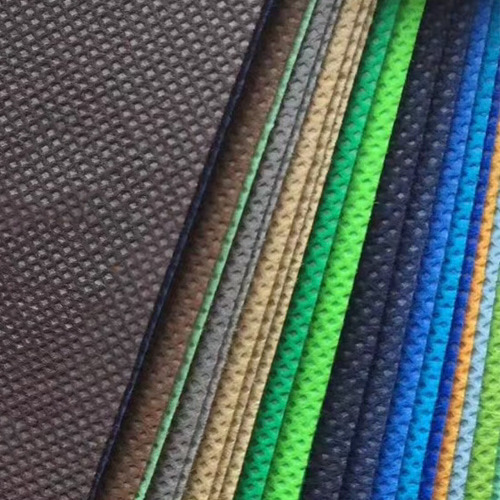

Needle-punched non-woven products are formed by fine carding, repeated precision needle punching or appropriate hot rolling treatment. Based on the introduction of two high-precision acupuncture production lines at home and abroad, high-quality fibers are selected. Through the coordination of different production processes and the matching of different materials, hundreds of different products are circulating in the market, including: geotextiles, geomembranes, velvet cloth, speaker blankets, electric blanket cotton, embroidery cotton, clothing cotton, Christmas crafts , Human leather base cloth, special cloth for filter material.

英语

英语 中文简体

中文简体