Twenty years ago, after my country's first spunbond nonwoven production line was established in Guangdong, by 2006, my country's total output of nonwovens exceeded 1.2 million tons, 4 times that of Japan and 6 times that of South Korea, becoming the world's largest nonwoven production line. The second largest producer of nonwovens. As a product of modern industrial civilization, nonwovens finally entered the homes of ordinary people. Our lives and the environment in which we live are changing because of it.

According to the plan of the Ministry of Communications, by 2010, my country will need 267,300 tons of automotive textiles. The survey shows that the sales volume of automotive textiles in my country is increasing at a rate of 15% to 20% every year. The domestically produced automotive textiles cannot meet the needs of the rapid growth of the automotive industry. $4 billion. There are hundreds of types of cars, transport vehicles, mini cars and agricultural vehicles in my country. Since 1995, the required automotive textiles have increased every year, but the current domestic production of automotive textiles is still far from meeting the increasing automotive industry. demand.

The "SARS" in 2003 let us know that masks made of non-woven fabrics are more antibacterial than gauze masks. From wound care gauze, masks, surgical isolation gowns, surgical gowns, and bandages, non-woven products have more uses due to their barrier properties, antibacterial properties, softness and comfort requirements. In addition, the field of medical textiles, because of its huge technological content and considerable profits, has also allowed more people to start a more in-depth development. It is understood that the development of medical textiles in various countries in the world is accelerating, and 17 textile research institutions in Germany have invested in the research and development of medical textiles. my country has also begun the necessary preparations and investment in this field.

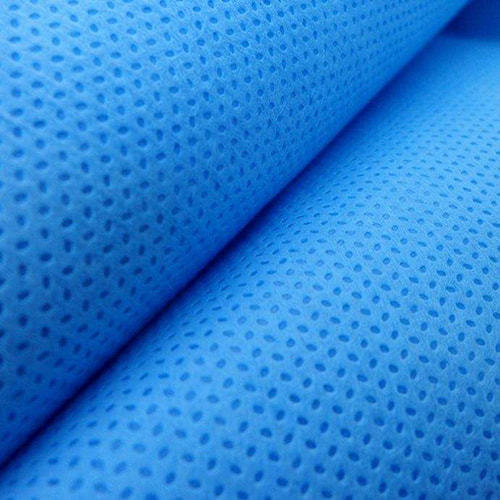

For a long time, the requirements for materials for sanitary products are soft, drapey, non-irritating to the skin, and good air permeability. While people continue to pursue comfort, the technological content of sanitary napkins, sanitary pads, training pants, etc. continues to improve. The specially treated spunbond non-woven fabric not only penetrates quickly, but also has good air permeability and softness, which can prevent wrinkling and twisting, and bring the most effective comfort to consumers. Just taking baby diapers as an example, non-woven materials are basically used in the surface layer, side edge, flow guiding layer, absorption layer, and back layer. As one of the greatest inventions of the 20th century, nonwovens are not only changing our lives, but also our ideas.

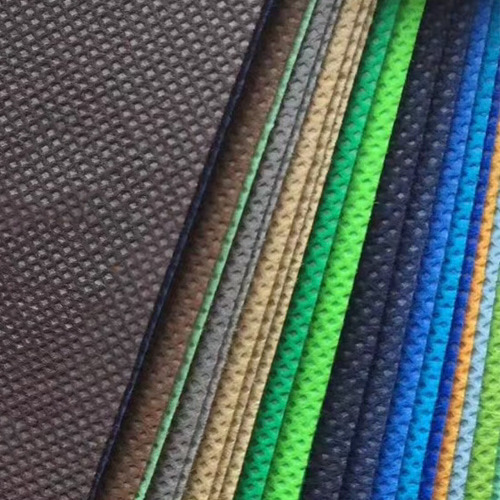

Due to its high tensile force, high tear strength, good uniformity, good softness, and rich colors, spunbond nonwovens have occupied an increasingly important position in household and packaging applications. In various brand stores, people see not only many well-known brand clothing, but also various matching suit sets; people not only see them in specialty stores, but also in large shopping malls and clothing wholesale markets. It also became a regular.

English

English 中文简体

中文简体