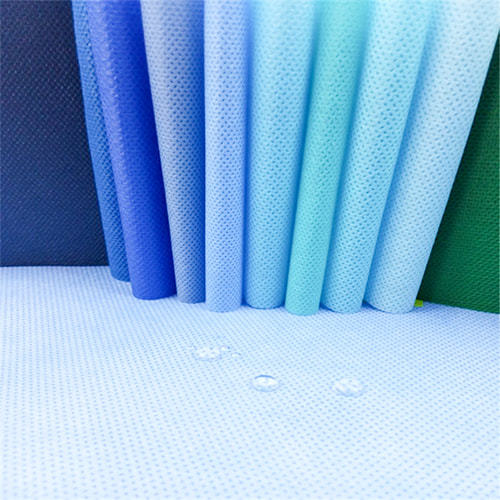

PP Spunbond Non woven fabric is an ideal insulator as it has the lowest thermal conductivity of all synthetic or natural fabrics. It also has high strength and is not flammable, making it the perfect choice for packaging applications.

Moreover, it is resistant to fabric bacteria and other microbes, and is long lasting against moths, mildew and molds. It is a non-flammable material and can be treated to become fire-retardant, as well.

It is manufactured using polypropylene by a simple process of drawing and hot rolling. Hence, it is an eco-friendly product that is widely used in sanitary materials, hygiene products and packing.

The production of PP spunbond non woven fabric is very simple, and the output level is large. The raw material of the PP non woven is carefully polymerized into a net through high temperature drawing and bonded properly to the fabric through hot rolling.

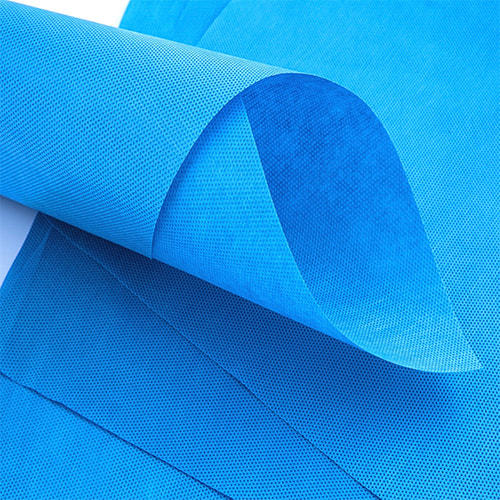

This type of fabric is a great choice for hygiene, medical and health care, bedding and home textile, automative, packaging, agriculture and horticulture, and building industries. It is soft to touch, offering excellent absorbency, air permeability and liquid repellency.

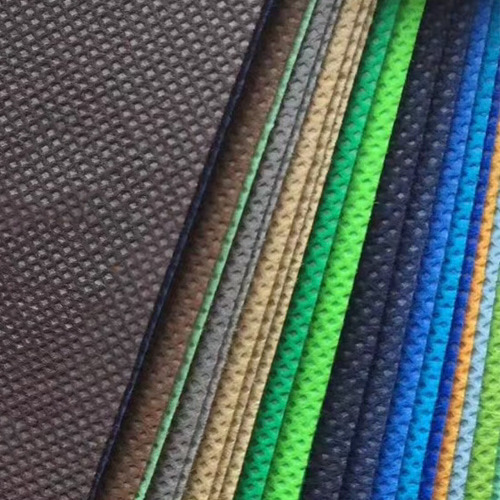

PP Spunbond non woven is made with a variety of different fibers such as nylon, polyester, polypropylene, and other plastics. The fibers are then mixed together to create a pliable material. The fabric is then rolled or twisted to form a sheet or web structure.

PP Spunbond is one of the most common types of spun bond fabrics available on the market today. It is a cost-effective alternative to traditional spunlace and SMS fabric. It is a versatile non-woven fabric that has a wide range of applications and can be bonded with various substrates to meet specific requirements.

英语

英语 中文简体

中文简体