PP spunbonded non-woven fabric is extruded, stretched, and formed into continuous filaments of polymers, and the filaments are laid into a net, and then bonded by the fiber web itself, thermally bonded, chemically bonded or mechanically reinforced to make it The fibers are networked into a non-woven fabric.

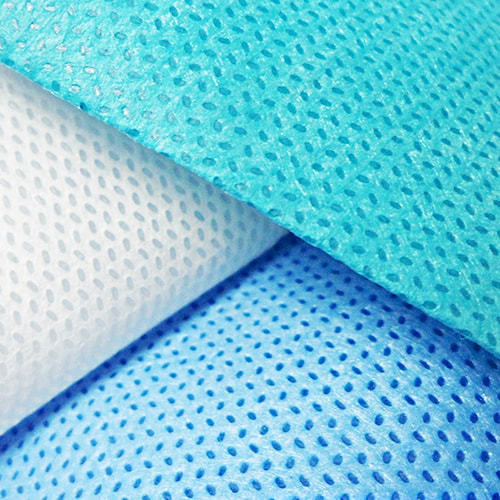

Spunbond non-woven fabric has good high temperature resistance, good high temperature resistance (polypropylene can be used in an environment of 150 °C, and polyester can be used in an environment of 260 °C for a long time), aging resistance, UV resistance, high elongation, Good stability, good air permeability, corrosion resistance, sound insulation, moth proof, non-toxic.

PP spunbond non-woven fabric PP is the raw material of polypropylene, that is, polypropylene fiber.

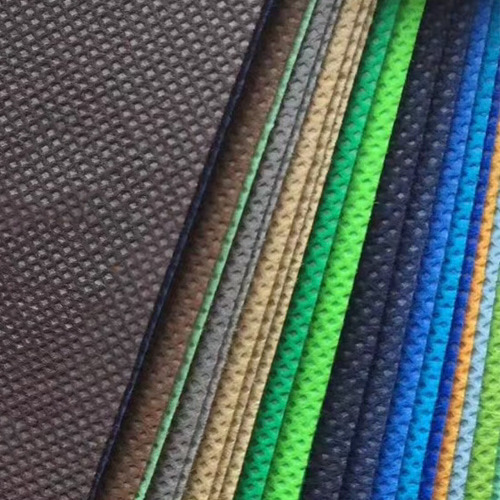

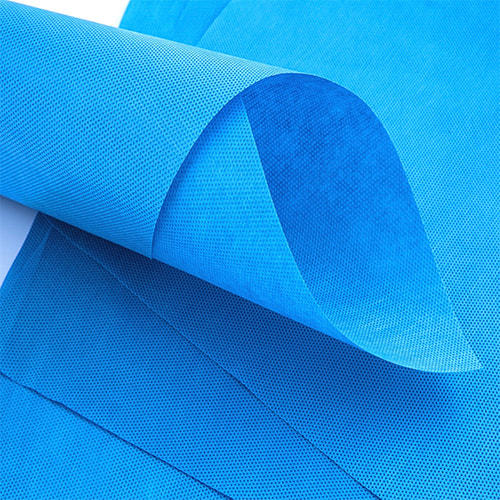

PP spunbonded non-woven fabric is a new generation of environmentally friendly materials, with the characteristics of waterproof, breathable, flexible, non-combustible, non-toxic and non-irritating, and rich in color. If the material is placed outdoors to decompose naturally, the longest lifespan is only 90 days, and it decomposes within eight years. It is non-toxic, odorless, and has no residual substances when burned, so it does not pollute the environment. It is a non-woven and non-woven fabric that does not need weaving. Cloth, fiber paper, composed of oriented or random fibers, produced by one-step process of high-temperature melting, spinning, steel, and thermal primary paper. Polypropylene is used as raw material, and it is polymerized into a net shape by high-temperature wire drawing, and then bonded to the cloth by hot rolling. Because the process is simple, the production volume is large, and it is harmless to the human body. With no warp and weft threads, it is very convenient to cut and sew. Therefore, it is widely used in various fields, such as medical non-woven fabrics, agricultural non-woven fabrics, industrial non-woven fabrics and packaging material non-woven fabrics.

英语

英语 中文简体

中文简体