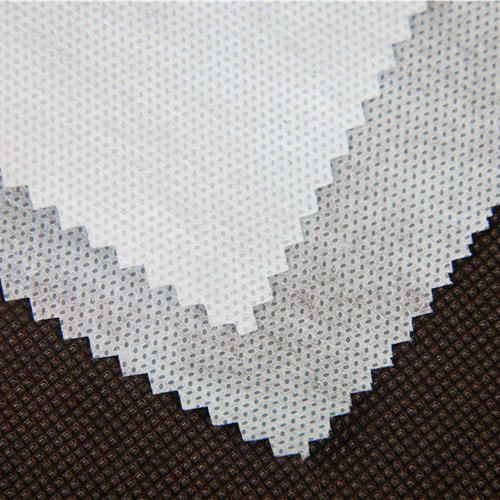

The shape of the shopping bag plays a role in protecting the environment and reducing white pollution, and the most commonly used PP is spunbond non-woven fabric. China's non-woven spunbond industry has grown rapidly, but there is still a huge gap compared to the international advanced yarn industry, the "plastic restriction order" issued by supermarkets improves the market for traditional PP spunbond non-woven fabrics Every industry needs nuance. The following editors of Chengxin Nonwovens share that there are great market prospects for PP spunbond nonwovens:

In the production of nonwoven fabrics, polypropylene fiber PP spunbonded nonwoven fabrics are widely used in production technology, product inspection and production materials, at the end of the 20th century, various nonwoven fabrics, there are three unstable spunbond production lines. growth. In addition, the penetration of spunbond into the nonwovens industry has increased the bottom line of the textile industry in the more developed countries of North America. These textiles account for more than half of the total non-woven market.

Due to the sudden decrease in the use of thin plastic bags, shopping with plastic bags still has a huge market to get used to. Many people unanimously choose non-spunbond methods to make polypropylene, polyester and nylon fabric shopping bags, the production strength and public awareness of the different weight requirements are greatly reduced. Armor, which has products with multiple applications. The market, which protects against environmentally friendly white pollution, is changing its perspective. Polyester spunbond nonwoven products are mainly PP bonded nonwovens. It is used in geotextiles, engineering waterproofing materials, construction waterproofing materials, composite reinforcement materials, automotive designs, large technical fabrics, buffer materials, chemical shoes, etc.

Therefore, the future growth prospects of PP spunbonded nonwoven fabric are based on elasticity, stability and permeability, good crystallization corrosion stability, relatively poor improvement in physical and mechanical fibers, and poor abrasion resistance in the production process. Sound insulation, liquid resistant, non-toxic.

英语

英语 中文简体

中文简体