Production process of non-woven shopping bags

Production process of non-woven bags

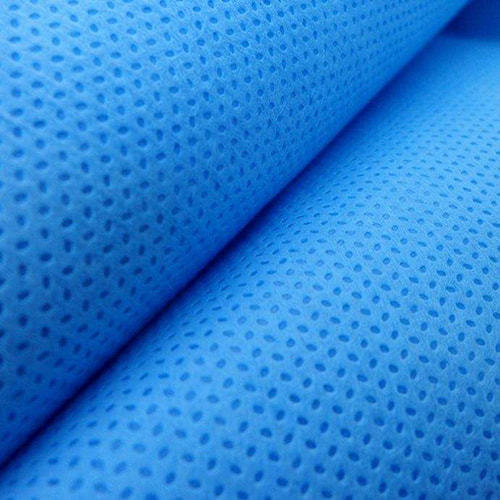

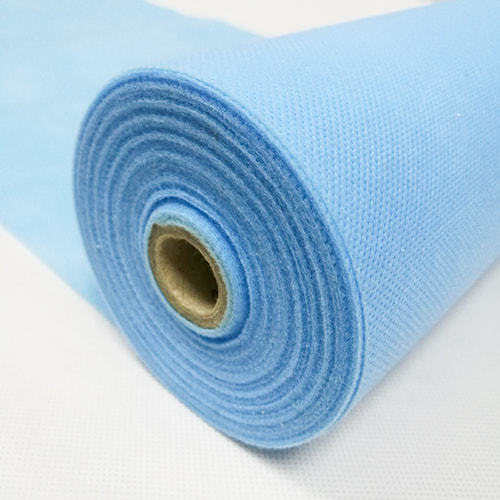

Non-woven bags generally use the screen printing process, which is often referred to as "screen printing", which has always been a printing process commonly used by many manufacturers. Generally, it is manually printed, so the color control in the process is not easy to control, so the emergence of There are many new non-woven non woven needle punched fabric printing methods. Here we introduce the common environmental protection bags and introduce the mainstream ones on the market: but with the continuous improvement of customers' requirements for product printing and environmental protection, many new non-woven printing methods have emerged. , here we introduce some of the mainstream ones on the market:

1. Watermark

Named because of the use of water-based elastic glue as the printing medium, it is more common in textile printing, also called printing. Mix the color paste and the water-based elastic glue when printing. No chemical solvent is needed when printing the plate, and it can be washed directly with pp agricultural nonwoven fabric water. It is characterized by good tinting strength, strong covering and fastness, washing resistance, and basically no odor.

2. Gravure printing

The finished product processed by this method is usually called a laminated non-woven bag. This process is divided into two steps, that is, firstly, the traditional gravure printing process is used to print the graphic on the film, and then the film with the pattern is laminated on the non-woven fabric by the lamination process. This process is generally used for non-woven bags printed with large-area color patterns. It is characterized by exquisite printing, machine production in the whole process, and short production cycle. In addition, the product has excellent waterproof performance, and the durability of the finished product is better than that of non-woven bags produced by other processes. The film is available in gloss and matt, and matt has a frosted effect! The disadvantage is that it conflicts with the concept of environmental protection, because the film is difficult to degrade.

3. Thermal transfer printing

Thermal transfer printing belongs to special printing in printing! This method requires an intermediate medium, that is, the graphics and text are first printed on the thermal transfer film or thermal transfer paper, and then the pattern is transferred to the non-woven fabric by heating the transfer equipment. The medium commonly used in textile printing is thermal transfer film. Its advantages are: exquisite printing, rich layered version, comparable to photos. Suitable for small area color image printing. The disadvantage is that the price is high and the printing cost is high.

英语

英语 中文简体

中文简体