Technical application of spunlace non-woven fabric

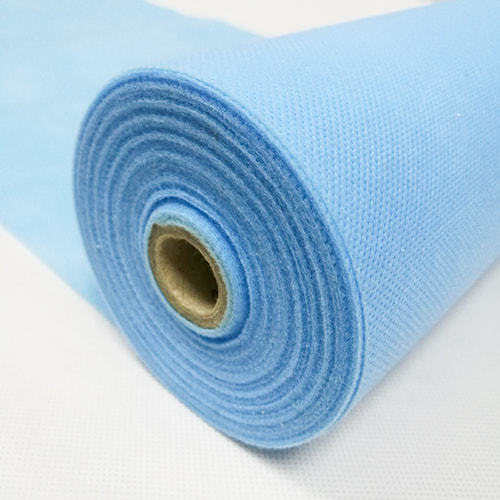

Applications

Spunlace non-woven fabrics are used for medical curtains, surgical gowns, surgical drapes, medical dressing materials, wound dressings, medical gauze, aviation wipes, clothing lining base cloths, coated base cloths, disposable materials, and advanced instrumentation wipes , Electronic industry high-grade wipes, towels, cotton pads, wet wipes, mask covering materials, etc.

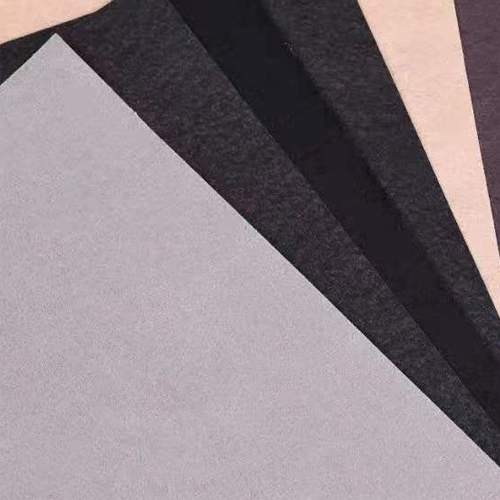

Product Features

Soft hand feeling, fluffy, high moisture absorption, with a certain oil absorption effect

Production technology

The research and development of spunlace composite technology not only overcome the limitations of some nonwoven products, increase the variety of colors, greatly broaden the application field of spunlace nonwovens, but also promote the development of spunlace technology and even the entire nonwoven process Development and improvement.

(1) Spunlace and wood pulp air-laid composite technology. Because the price of wood pulp is much cheaper than the staple fiber commonly used in spunlace, and the fluff pulp has good moisture absorption and hand feeling, the product made is cheaper than the product made of all fibers, and the price is very competitive. The requirements on the filtration system are very high. The product can be used as the inner core material of wipes (70%g/m2), diapers and sanitary napkins. The spunlace and wood pulp air-laid composite equipment includes Fleissner's Aquapulp and Perfojet's Airlace.

(2) Spunlace and filament spunbond web composite technology. The composite product of this method has both the strength of spunbonded nonwovens and the better absorption performance of short fibers than the commercial ones, and is more uniform and softer than spunbonded nonwovens, has the function of water and oil absorption, and has higher strength. It can be used as food wrapping cloth. , Decorative cloth and cleaning cloth, etc. The spunlace and spunbond composite equipment includes Flerssner's Aquqspun and Aquasplit. And Freudenberg's Evolon processing technology.

(3) Spunlace and wet-laid composite technology. The typical process Detex's Hydraspun technology is composed of Detex's wet-laid technology combined with the Soflom spunlace method registered by Unicharm of Japan. The strength and softness of Hyderaspun wet spunlace nonwovens are equal to or even better than traditional dry spunlace nonwovens, and the wet spunlace nonwovens do not shed dander, and the seam stretch strength is dry spunlace Twice the non-woven fabric, especially suitable for the field of clothing.

英语

英语 中文简体

中文简体