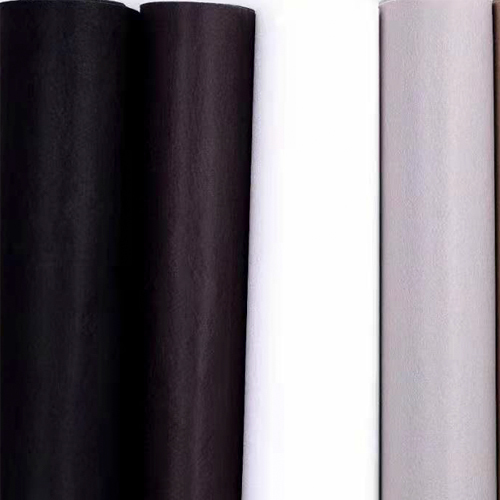

PP spunbond non-woven fabric, also known as polypropylene spunbond non-woven fabric, is a type of non-woven fabric produced through a spunbond process. The process involves the extrusion of polypropylene fibers, which are then spun and bonded together to form a non-woven fabric. PP spunbond non-woven fabric is widely used in a variety of applications, such as medical and hygiene products, agricultural coverings, geotextiles, furniture and bedding products, packaging, and more.

Some of the advantages of PP spunbond non-woven fabric include:

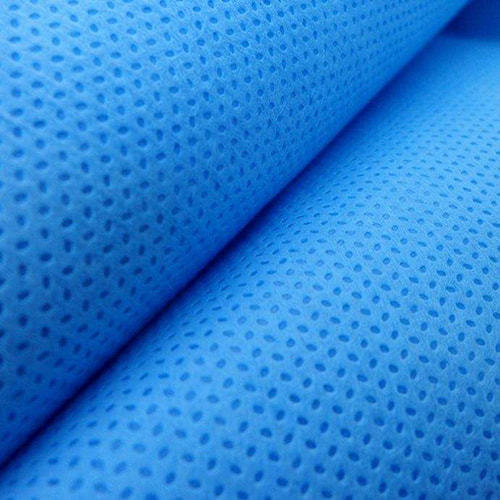

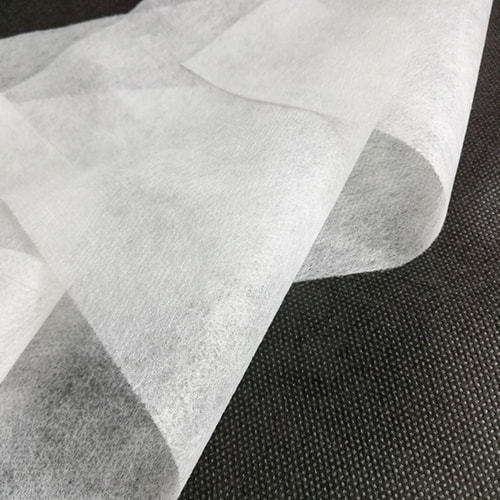

1. Lightweight and breathable: PP spunbond non-woven fabric is very light in weight, and it has excellent air permeability, which makes it comfortable to wear.

2. Strong and durable: PP spunbond non-woven fabric is very strong and durable. It can withstand wear and tear, and it has a long service life.

3. Good barrier properties: PP spunbond non-woven fabric has good barrier properties against water, dust, and particles. It can help to protect products from contamination.

4. Easy to process: PP spunbond non-woven fabric is easy to process and can be cut, sewn, and heat sealed to create products of various shapes and sizes.

5. Cost-effective: PP spunbond non-woven fabric is cost-effective compared to other materials, and it is also recyclable and eco-friendly.

PP spunbond non-woven fabric is a versatile material that can be used in a wide range of applications. Its lightweight, breathability, and barrier properties make it a popular choice for medical and hygiene products, while its strength and durability make it a good choice for durable products like geotextiles and furniture and bedding products.

英语

英语 中文简体

中文简体