What are the characteristics and uses of spunbond non-woven fabrics:

The main materials of spunbond non-woven fabrics are polyester and polypropylene.

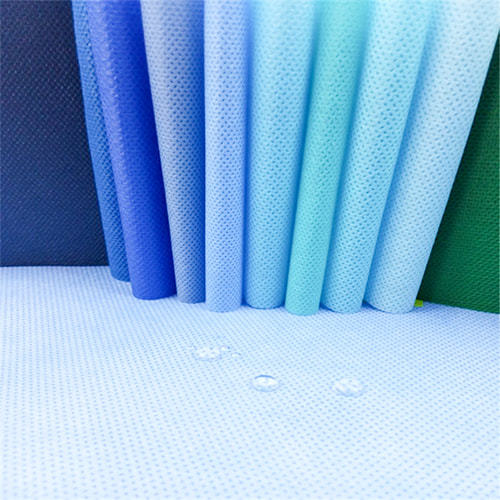

The main products of spunbond non-woven fabrics are polypropylene and polyester (long fiber, short fiber) non-woven fabrics. Our most common and commonly used applications are non-woven bags, non-woven packaging, etc.; for spunbond non-woven fabrics It is easy to identify and generally has good two-way fastness. Generally, the nip point of spunbonded non-woven fabrics is diamond-shaped.

The application level can also be used for flower packaging cloth, luggage cloth, etc., wear resistance, firm hand feel, etc. characteristics, making it the best choice for making this type of product.

Spunbond Spunbond Non-woven Fabric Process

Polypropylene: polymer (polypropylene + back material)-large screw high temperature melt extrusion-filter-metering pump (quantitative delivery)-spinning (spinning inlet up and down drawing suction)-cooling- Air traction-net curtain formation-upper and lower press rolls (pre-reinforcement)-rolling mill hot rolling (reinforcement)-winding-inverted cloth slitting-weighing and packaging-finished product storage

The main materials of spunbond non-woven fabrics are polyester and polypropylene.

The main products of spunbond non-woven fabrics are polypropylene and polyester (long fiber, short fiber) non-woven fabrics. Our most common and commonly used applications are non-woven bags, non-woven packaging, etc.; for spunbond non-woven fabrics It is easy to identify and generally has good two-way fastness. Generally, the nip point of spunbonded non-woven fabrics is diamond-shaped.

The application level can also be used for flower packaging cloth, luggage cloth, etc., wear resistance, firm hand feel, etc. characteristics, making it the best choice for making this type of product.

Spunbond Spunbond Non-woven Fabric Process

Polypropylene: polymer (polypropylene + back material)-large screw high temperature melt extrusion-filter-metering pump (quantitative delivery)-spinning (spinning inlet up and down drawing suction)-cooling- Air traction-net curtain formation-upper and lower press rolls (pre-reinforcement)-rolling mill hot rolling (reinforcement)-winding-inverted cloth slitting-weighing and packaging-finished product storage

Polyester: processed polyester chips-high temperature melt extrusion of large stalk stalks-filter-metering pump (quantitative conveying)-spinning (up and down drawing and suction at the spinning inlet)-cooling-air traction ——Net curtain forming——Upper and lower press rolls (pre-reinforcement)——Hot rolling on rolling mill (reinforcement)——Winding——Inverted cloth slitting——Weighing and packaging——Finished products

英语

英语 中文简体

中文简体